For a long time in the past, our industrial cleanroom sponge swab were distinguished in the industry by their density, which is kg/m3, the weight of a sponge per cubic metre. Commonly used sponges are divided by structure into three types of high density sponge, medium density sponge and low density sponge. According to the national customs department’s explanation is the density ≧ 45 for high density, density between 45 ~ 18 for medium density, density ≦ 18 for low density.

High-density sponges have many holes and are very full. Generally speaking, high-density sponges have high hardness, but it is not ruled out that some high-density sponges will add super soft additives to make the sponge super soft, used as sound-absorbing cotton, sofa cushions, and soft package materials. Medium-density, low-sponge sponges are used as general protective materials. The softness and hardness of sponges with the same density are also different.

With the improvement of sponge technology, it is no longer advisable to judge the density of sponge simply by weight. In fact, the high-density sponge under the current production process is much lighter than the previous processed sponge. Therefore, we introduced a more professional technical standard to evaluate the density of sponges, PPI.

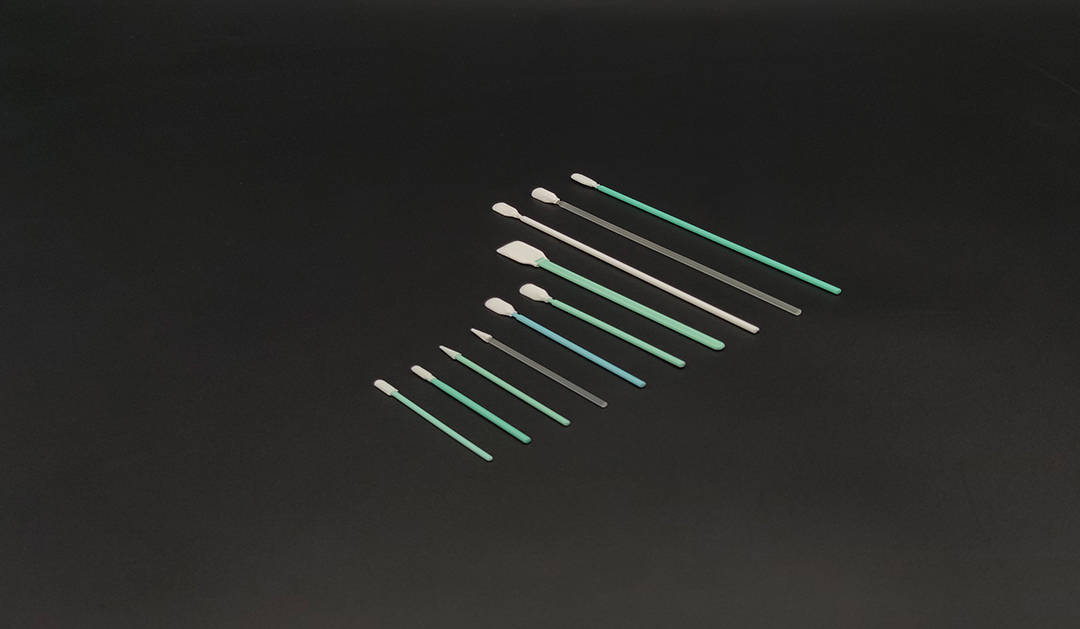

The sponge cleanroom swabs produced by Miraclean Technology company use 100 PPI polyurethane sponge. The sponge is moderately soft and hard, and the PPI index is reasonable. While maintaining normal adsorption capacity, it minimizes the occurrence of crumbs. In addition to the PPI standard, we also refer to the common density standard. We also provide high-density sponge and medium-density sponge as the material of the cotton swab head. Their corresponding densities are 45 kg/m3 and 30 kg/m3 respectively.