The circuit board is also called a PCB board, or a substrate. Due to some reasons, there is dust, dirt or even oxidation on the surface, which affects the normal use of the circuit board. Therefore, in the process of circuit board production and use, regular cleaning and maintenance should be carried out to maximize the life of the circuit board.

It is more common to use a brush dipped in board washing water to scrub. This method has a good cleaning effect on circuit boards. Using special board washing water or thinner will not conduct electricity, will not damage electronic components, and it is easy to evaporate, so that the circuit board should be kept dry. This method is commonly used in the electronic maintenance industry or in electronic workshops and R&D departments, which is simple and convenient.

Most of the brushes for cleaning circuit boards used to use wooden cotton swabs, which is what we usually call cotton swabs. The cotton swab has a very low cost, can be produced in large quantities, and can also meet the anti-static requirements of circuit boards. But there is a problem, that is snagging. Because the head of this cotton swab is made of cotton, when wiping the circuit board, it is particularly easy to be caught by the protrusions on the board and stay on the board, which will cause immeasurable damage to the service life of the board. In addition, wooden poles and paper poles are easy to bend and break, which has a great impact on work efficiency.

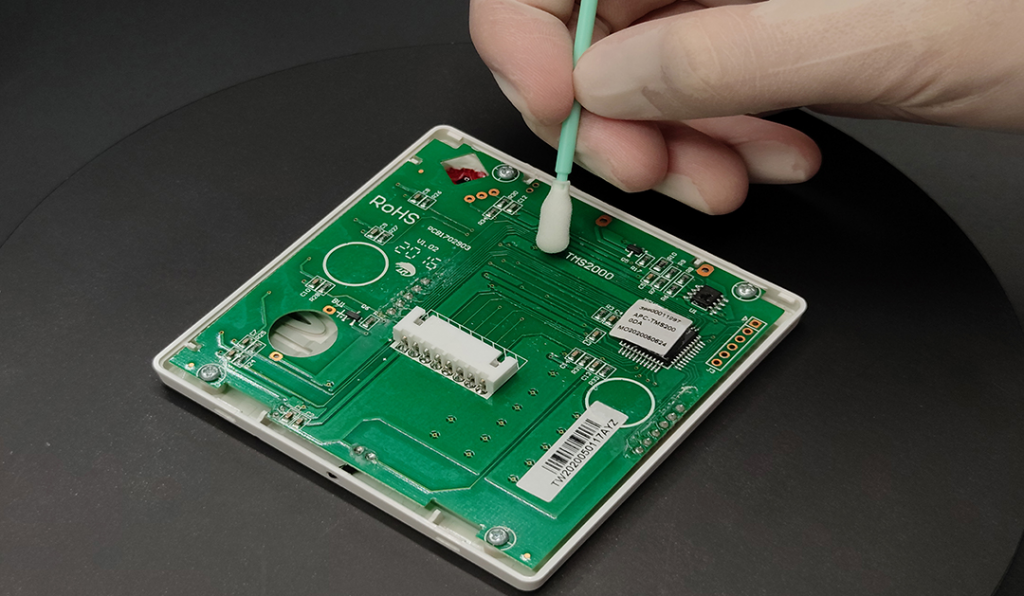

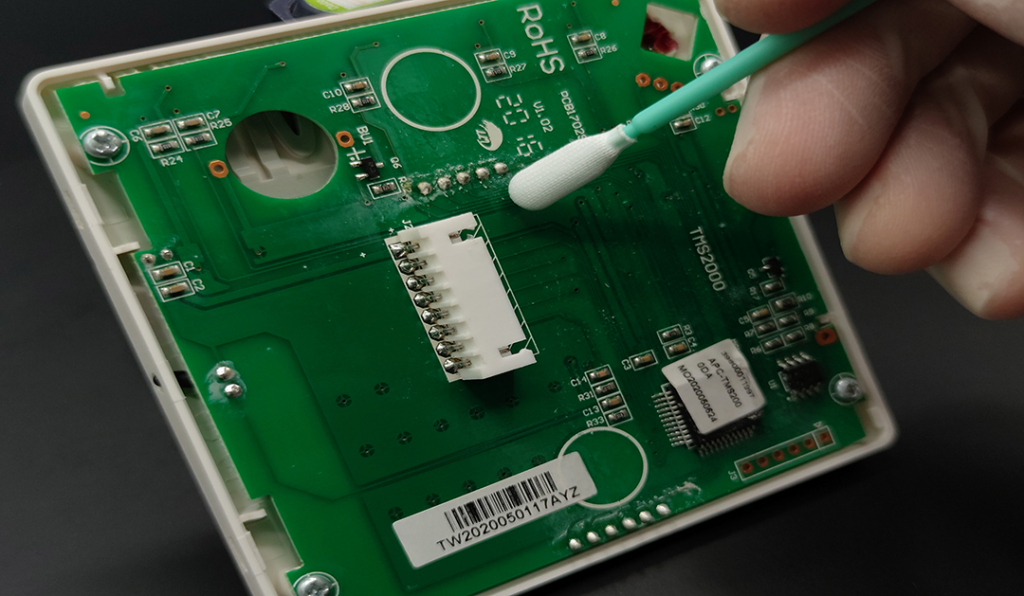

In fact, in addition to the traditional cotton swabs with wooden stems and paper stems, there is another tool that works very well, that is, purification cotton swabs. The dust-free purification cotton swabs produced by Miraclean Technology Co., Ltd. have styles designed for circuit board cleaning. The head is made of 100PPI polyurethane sponge and polyester fiber, which ensures good wiping performance and prevents snagging. The shaft is made of lighter and tougher polydiene material, which can be used with other cleaning agents to further improve the performance of the swab. There are also pointed cleaning cotton swabs specially used for the gaps of electronic components, which maximizes the cleaning quality.